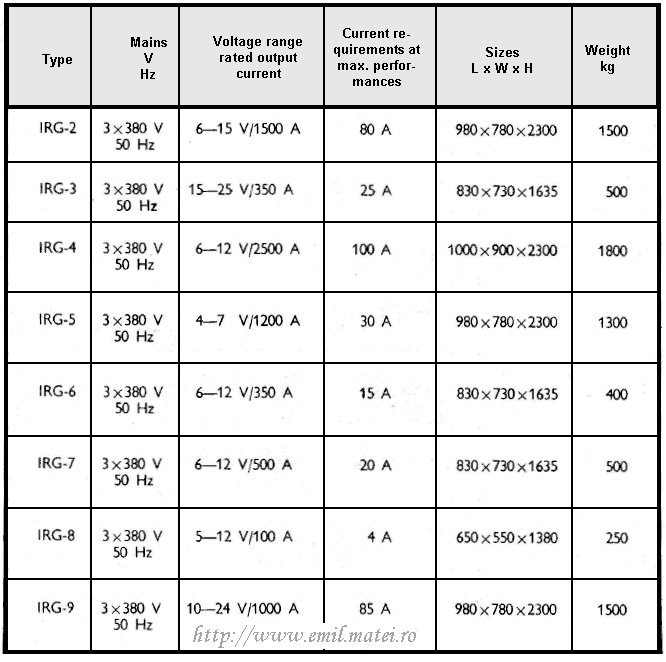

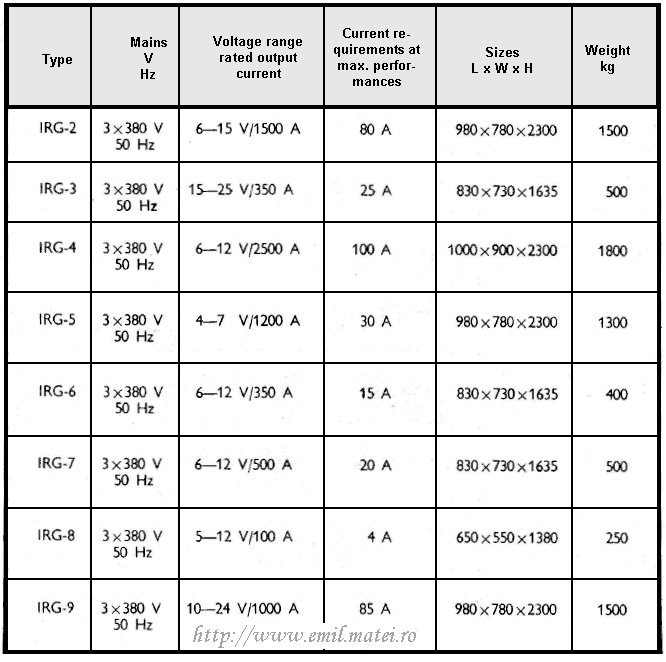

Type IRG - Old Romanian electroplating rectifying plants

Redresoare de putere pentru galvanizare tip IRG

Redresoare de putere pentru galvanizare tip IRG

IRG type rectifying plants are supply sources for galvanizing dry baths fitted with silicon

diodes whose output voltage is continuously controlled through magnetic amplifiers, in either

the stabilized or the non-stabilized version.

These plants can be used as DC supplies for other equipment as well, provided their requirements are matched by the IRG performances.

These plants can be used as DC supplies for other equipment as well, provided their requirements are matched by the IRG performances.

IRG rectifying plants feature a compact single-block system containing in a metallic cabinet

the whole electronic equipment needed for control, protection, setting, adaptation and measuring

purposes, terminals for the a.c. mains connection and for the d.c. output included.

Provision is made for accidental contacts and for earthing.

Except for the IRG-8, which is natur:ally vented, all other versions have forced ventilation, the fan being included in the cabinet.

The plants can be mounted either in the same rooms as, or in rooms separate from the electroplating baths.

When mounted in the same rooms, they should be placed at a certain distance from the baths and steps should be taken for a positive ventilation so as to avoid the accelerated corrosion of electric and electronic components housed in the cabinets.

Versions IRG-2, IRG-4, IRG-5 and IRG-9 are fitted with remote control desks.

Connections between these control desks, which are located in the same room as the controlled electroplating bath, and the relevant rectifying plants are made through multiple-wire cables (for instance twelve 1sq. mm copper wires).

IRG rectifying plants offer the following benefits:

Provision is made for accidental contacts and for earthing.

Except for the IRG-8, which is natur:ally vented, all other versions have forced ventilation, the fan being included in the cabinet.

The plants can be mounted either in the same rooms as, or in rooms separate from the electroplating baths.

When mounted in the same rooms, they should be placed at a certain distance from the baths and steps should be taken for a positive ventilation so as to avoid the accelerated corrosion of electric and electronic components housed in the cabinets.

Versions IRG-2, IRG-4, IRG-5 and IRG-9 are fitted with remote control desks.

Connections between these control desks, which are located in the same room as the controlled electroplating bath, and the relevant rectifying plants are made through multiple-wire cables (for instance twelve 1sq. mm copper wires).

IRG rectifying plants offer the following benefits:

- being dry (no oil) no special lay-out, location or other problems are raised;

- continuous operating conditions (DA = 100 per cent);

- since the protection features are incorporated in the cabinets, on mounting the equipment only the connections to the a.c. mains and to the electroplating baths are to be made;

- the continuous control of the operating voltage and current is a real asset in obtaining the working performances desired;

- the lack of moving components (except for the fan), added to the use of semiconductor devices (silicon diodes) are the guaranty of a permanent operation, of a high reliability and of a low servicing effort.

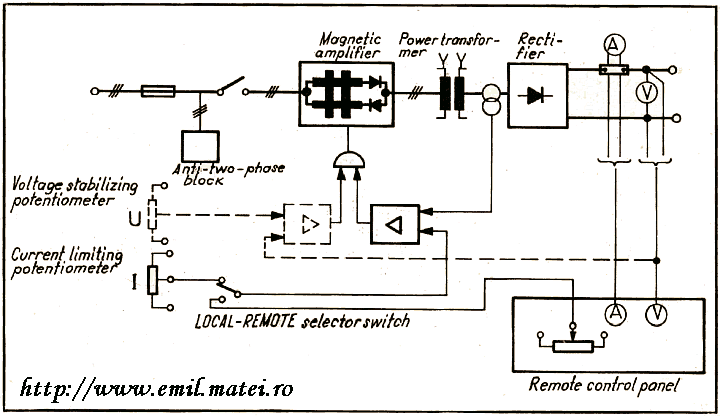

Standard plants usually include the following components:

- adapting transformer (supply from the mains);

- magnetic amplifiers to adjust the secondary voltage;

- three-phase rectifying bridge including silicon power diodes fitted with aluminium radiators to provide forced air cooling;

- contactor on the supply side;

- Protection components:

- fuses;

- supply thermal relays;

- protection against two-phase operation;

- transistorized current limiting device to cope with excessive loads or with short-circuits in the bath;

- control and adiusting components:

- on-off knobs - on the front panel of the cabinet;

- voltage and current adjusting potentiometer (mounted on the front panel and acting upon the magnetic amplifiers control current);

- transistorized control block;

- measuring components:

- DC voltmeter

- DC ammeter both mounted at the output

- signalling lamps for the connection to the mains and the satisfactory operation of all plants.

The principle wiring diagram is shown in figure:

Design versions of rectifiers fitted with remote control desks are high capacity units of 1000 A

and above, used to supply high productivity electroplating bath. They are mounted in separate rooms

for reasons already shown before; the lengths of connecting cables should not exceed 50 m.

All types of rectifiers are built in two versions as a function of the user's requests namely:

The current limiting feature is continuously adjustable up to 1.4 Irated for both design versions. For those constructive versions fitted with an automatic voltage stabilization feature, letter S is added to the rectifier symbol. Example: IRG-2 S - rectifying plants, type 2, for electroplating baths with voltage stabilization feature.

All types of rectifiers are built in two versions as a function of the user's requests namely:

- with current limiting feature;

- with voltage stabilizing feature: max fluct. +/-2 per cent for changes of +/-10 per cent in the supply mains, and from 0.1 to 1 Irated in the load current; current limitation (IU characteristic).

The current limiting feature is continuously adjustable up to 1.4 Irated for both design versions. For those constructive versions fitted with an automatic voltage stabilization feature, letter S is added to the rectifier symbol. Example: IRG-2 S - rectifying plants, type 2, for electroplating baths with voltage stabilization feature.

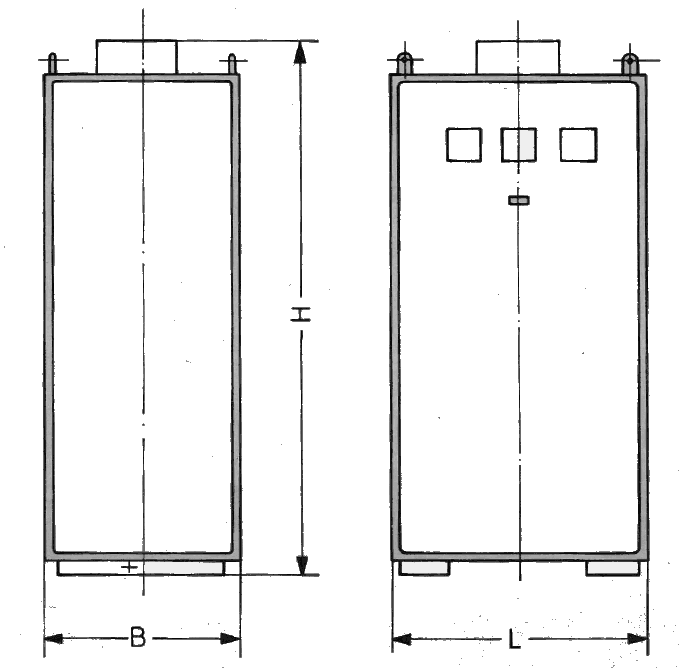

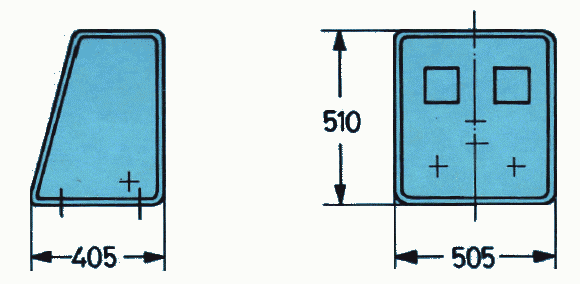

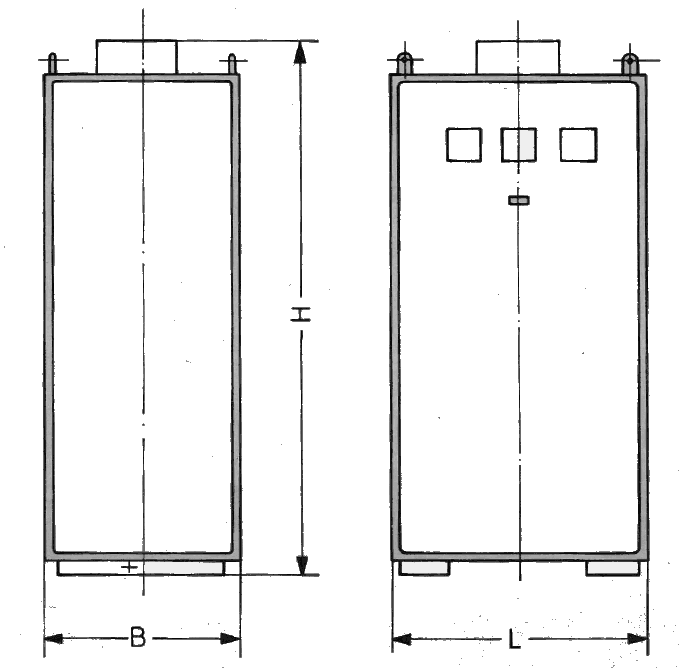

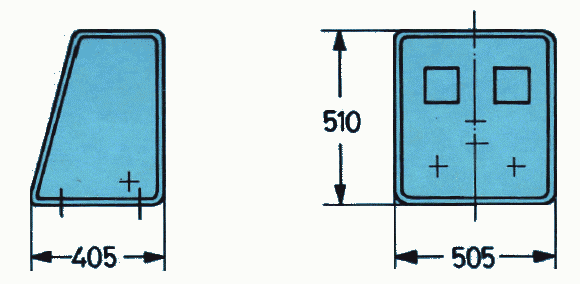

The shape and sizes of remote control cabinets and desks are shown in figures:

IRG TYPE ELECTROPLATING RECTIFYING PLANT

REMOTE CONTROL DESK

All informations are from ELECTROTEHNICA Enterprises, Bucharest, Romania.

IRG TYPE ELECTROPLATING RECTIFYING PLANT

REMOTE CONTROL DESK

All informations are from ELECTROTEHNICA Enterprises, Bucharest, Romania.